Valves are one of the most crucial components in any plumbing system. They basically control the start and stop of liquid flow and prevent unwanted flows and leakages. Ball valves and gate valves are the most popular valves used to control the flow of fluids in the market currently.

These two types of valves can be shipped to whatever place you are located in the stores around you that don’t have them in stock. If you are not keen, differentiating ball valves and it can be so confusing. Knowing how the two functions are very important when choosing which one is the best fit for the kind of application you need. This article will focus on gate valves vs ball valves. What they are, their types, advantages, and disadvantages.

Table of Contents

What Are Ball Valves?

Ball valves are part of the valve family of quarter-turn. They take a 90 degrees turn to close and open them. Ball valves are also referred to as shut-off valves. They are the only way to shut off the water flow immediately.

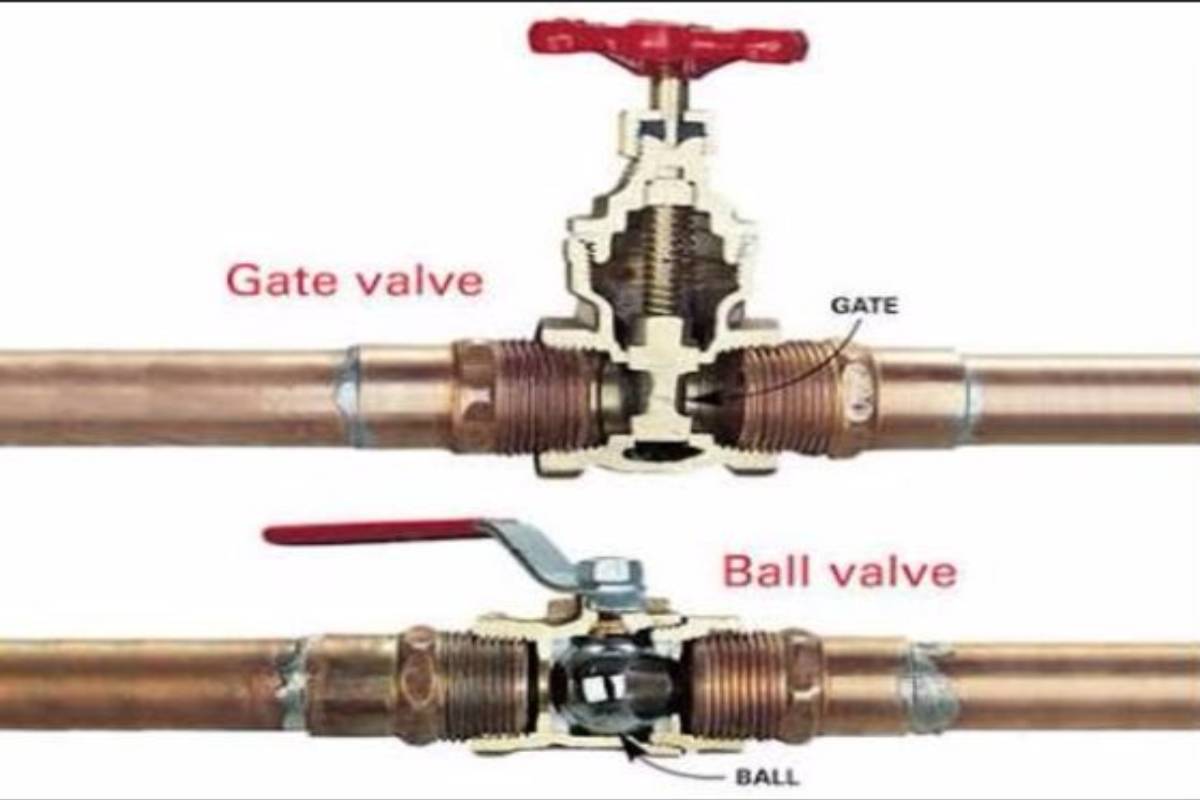

The design of ball valves enables them to shut off the water flow using spheres or balls that are small inside them. The spheres or balls have an opening inside them. When on, the opening will be in line with the pipe and water will be allowed to freely flow. When the ball valve is off, the opening will be perpendicular to the water flow. This completely stops the water flow.

Flow is controlled with a level in all ball valves. When the lever is placed perpendicular to the pipe, water is allowed to freely flow. When the lever is moved at 90 degrees angle the flow will stop. There are different types of ball valves which mostly depend on the material used to manufacture the balls.

- Stainless steel ball valves

- Bronze ball valves

- Brass ball valves

- PVC ball valves (Polyvinyl Chloride)

- CPVC (Chlorinated Polyvinyl Chloride) ball valves

- Chrome ball Valves

- Titanium ball valves

Advantages Of Ball Valves

- Ball valves are controlled with lesser force compared to other valves. Installing and handling them is very easy, especially the plastic ball valves.

- Ball valves of high quality last for longer periods and provide safe service under the right conditions. They are less prone to damage as compared to other valves. The plastic ball valves are not susceptible to corrosion. This means there will be fewer repairs but maintenance is essential.

- Ball valves are very affordable. They are bought at a lower cost than other types of valves.

- They are efficient. Ball valves don’t require any kind of lubrication for them to function properly. They provide a tight seal with low torque.

- They are very strong. Ball valves regulate and maintain high volume, pressure, and very extreme temperatures without being damaged.

- Ball valves provide leak-proof services

- Using ball valves requires fewer valves compared to globe and gate valves. This is because of their multi-designed flexibility.

- Ball valves come in various shapes and sizes. This makes them flexible for different industrial applications. Such industries use the ball valves to regulate gases and fluid flow.

- Ball valves are lighter compared to gate valves.

- Ball valves have smaller dimensions compared to gate valves.

What Are Gate Valves?

Gate valves are part of the family of linear motion valves. These kinds of valves are also referred to as slide or knife valves. It have wedged or flat discs which function as gates. The gate regulates fluid flow inside the valves. They are shut-off valves that have throttling capacity. They are mostly preferred for flow media that is thick.

The discs in the valves which are flat make it easier to cut through such thick media. It also belong to the rotary family. The wheels need to be rotated for the disc to open. In order for the disc to be in a closed position, the gates have to move downward and in between the two seats positioned on the upper part of the disc and also the bottom part. There are different types of gate valves depending on the material used to manufacture them.

- Forged steel gate valves

- Gunmetal stainless gate valves

- Alloy steel gate valves

- Cast carbon steel gate valves

- Ductile iron gate valves

- Cast iron gate valves

Advantages of Gate Valves

- They are perfect for pipelines that flow direction can be changed. It provide clear media flow from any direction of the valve body.

- Gate valves have a shorter length compared to the globe valves. This makes clacks of the gate valves align with the body of the valve.

- They are energy efficient. They use less power during their opening and closing. In these valves, the direction of the movement lies perpendicular to the direction of the media flow.

- It have a good deal of functioning. This makes them less eroded when open.

- Their valve bodies are easier to operate than in other valves.

Conclusion

Both the gate and ball valves serve a specific purpose. They also have their advantages and disadvantages which should be considered before choosing the appropriate valve for your application. Going for the right valve is an assurance that your plumbing system will serve you well. Contact us in case of any inquiries about the different types of valves and how to purchase quality ones.